Benefits Associated with the Use of CNC Machines

Science and technology development has been the current norm in today’s world. Through technology, work has been made easier, increased human productivity, and produced practical solutions to theoretical problems. Traditionally, mechanists have been crafting machine operations that are prone to human-error lowering their accuracy and efficiency. Therefore, the CNC machine came into existence to salvage the manufacturing industries.

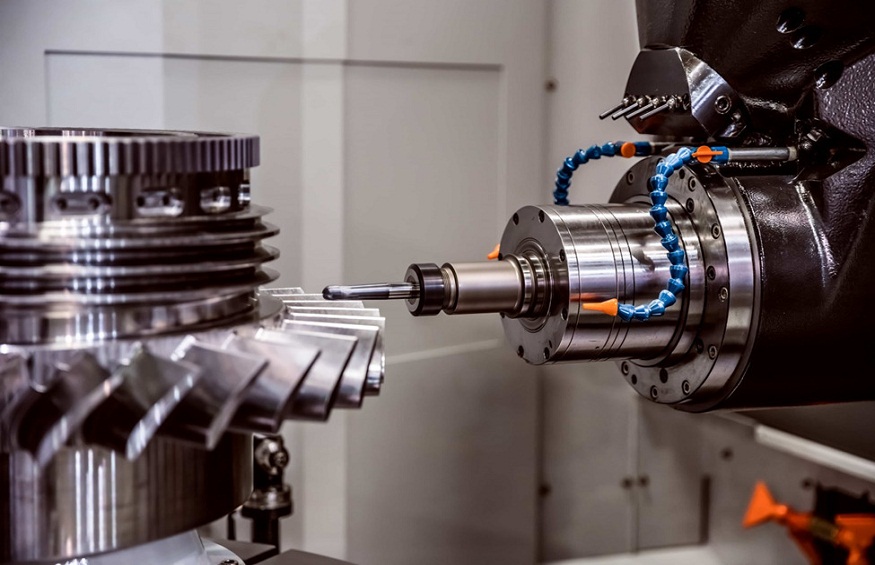

What is a CNC machine? CNC stands for computer numerical control. Hence, we can describe a CNC machine as an atomized tool used in manufacturing to perform a complex array of services, including carving, milling, patching. The machines are operated by a pre-programmed computer software controlling all machining tools in the production line. Adoption of the CNC machining is benefiting the manufacturing industry. Buy CNC machine and enjoy the multiple benefits they harbor compared to manual operations. Our article notes some of the benefits associated with the use of CNC machines.

Benefits of CNC Machines

It’s flexible

CNC machines are run by pre-set computer software. This means that they are readily customizable one doesn’t have to spend a lot of work dismantling the entire machine to fit in a new product. In a batch production system, CNC machines simplify new product development and eliminate the mold replacement hassle during production.

Maintain product Consistency

When you buy CNC machine, this is 100% assurance of improving and maintaining your productions’ quality. CNC machines are computer-controlled, meaning once the machine has been programmed to accommodate the processing needed. One can produce a batch with consistent quality parameters. Unlike manual machining, the CNC works as per the calibrations unless you change the control panel’s instructions.

Precise and accurate processing

CNC machining processing accuracy is quite remarkable compared to its competing manual methods. With the set error allowance, the CNC machine will operate on digital signals such that in case of a shift, one can detect it early in advance. Once the machine has been calibrated, the process is replicated on similar products improving its accuracy and precision.

Less expensive

The use of CNC machining in production; milling, carving, etc., is quite pocket-friendly. How? The owner will spend more money during the purchase and installation of the machine. However, unlike manual machining, which requires single-person per machine operation, the CNC requires a few skilled personnel. CNC machining lowers the numbers of workers need in production areas.

Additionally, the machines work with great precision and accuracy. This lowers the number of manufacturing wastes translating to low production loss and increases profits.

Safe working conditions

Human resources are the key requirement to increase a company’s products and meet their goals. The working environment should be safe and clean to protects the health of all workers. Working with CNC machines, they are pre-set before the processing starts. Also, the CNC machines are operated behind secured doors minimizing human traffic in the production areas hence maintain a secure production environment. The operator will program all the processing information need and keep monitoring plan. Adding to the CNC machining safety, the tools have a compact design that easily fits the set grounds.

In summary

Manufacturing processes were invented to add value to products. Although we are moving to achieve the organization’s goals, we better invest in a quality machine, like the CNC machines, making the processing work simple, accurate, and admirable.